Unique technology to protect Johan Castberg's production vessel from fire and extreme weather

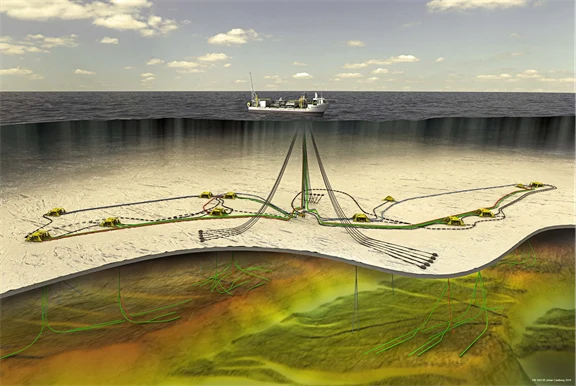

Approximately 250 km from Hammerfest lies the Johan Castberg oil and gas field. Here, a special vessel for production and storage, filled with Norwegian-developed technology, has been constructed to aid in the extraction of oil and gas from this field.

The vessel, anchored in one of the world's toughest marine climates, demands high-quality technical solutions. Therefore, Aker Solutions and Equinor have chosen a unique solution developed by Protan and the Norwegian fire safety company Firesafe Energy AS to protect the assets and installations on the vessel's deck from the extreme Arctic climate.

Equipped in Norway, the ship is classified as an FPSO, short for Floating Production, Storage, and Offloading platform. At the Kværner shipyard in Stord, Norway, the vessel's deck was equipped with a series of large process modules and technical installations, including extensive living units for up to 120 cabins. It is these living units that are protected by the solution developed by Protan/Firesafe.

"In short, this involves 700 meters of flexible fire barriers that will be installed between the various modules and barrier walls on the complex deck of the production vessel," explains CEO of Firesafe, Erik Ulevik.

These fire barriers are made of extremely fire-retardant materials developed to prevent explosions and fires in the petroleum industry. They were welded between the massive modules and deck sections on the nearly 300-meter-long vessel. The goal of the barrier walls is to ensure safe evacuation by stopping the spread of fire, directing surface water away, and protecting people and installations from wind, rain, and falling ice.

Production at Johan Castberg is scheduled to begin by the end of 2024, with the field expected to have a lifespan of 30 years. Since the same production vessel will serve this extreme climate throughout the period, there are particularly high demands on the quality of the materials used on the vessel. This, of course, applies to the fire barriers on the deck. To ensure this extremely high quality, the products are covered with Protan materials, benefiting from Protan's expertise in membrane production and experience in the oil and gas industry since the 1970s.

Protan's PVC-coated fabric covers are highly durable and weather-resistant, with applications in various regions worldwide, from the Arctic to the tropics. The equipment on the deck of the Johan Castberg vessel will, therefore, be well-protected against both winter storms and fire with the Protan/Firesafe solution.

It is estimated that the development of the Johan Castberg field will cost up to 80 billion Norwegian kroner, and it is expected to produce between 450 and 650 million barrels of oil in its lifetime. As the northernmost oil field ever established on the Norwegian continental shelf, it is reassuring to know that both people and installations will be safely protected with Protan and Firesafe's unique products when the vessel starts production at the end of 2024.

Protan 180 Fire Shield is a membrane with a high degree of flame retardancy. Protan 180 Fire Shield is a 1900 g/m2 PVC-coated membrane designed for high performance and robustness. The base textile consists of glass with steel wires and basalt fibers for optimal performance. Protan 180 meets the fire classification IMO 2010 FTPC. Learn more about Protan 180 Fire Shield.