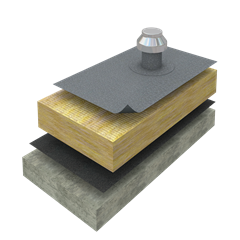

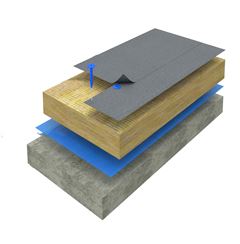

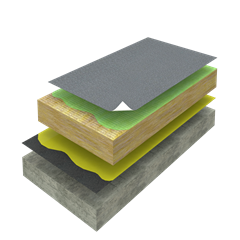

Pre-Fabricated System

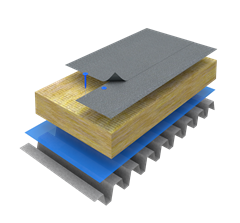

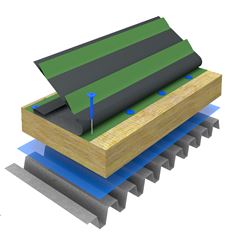

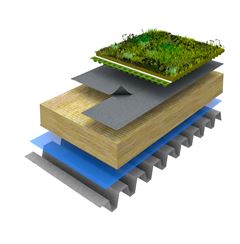

The Protan Pre-Fabricated system is a mechanically fixed roof system that makes use of Protan’s unique, prefabricated rolls of G or SE membrane.

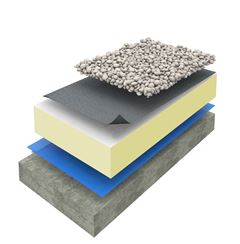

A Protan approved polyethylene vapour control layer is loose-laid over the structural roof deck, followed by Protan-approved insulation and prefabricated Protan G (for protected roof systems) or SE (for exposed roof systems) PVC single-ply membrane.

The prefabricated Protan membrane is mechanically fixed to the structural roof deck by fasteners and telescopic tube washers (the density of which is determined by a wind load calculation completed by Protan’s Technical Services Department) through secret-fix strips factory-welded to the reverse side of the membrane. The rolls of prefabricated Protan membrane overlap each other by a minimum of 40mm and are welded together using hot air to create a homogenous waterproof seal.

As no adhesives or solvents are used, all materials and components of the Protan Pre-Fabricated system are fully recyclable.

Pre-Fabricated Protan PVC single-ply membranes are ideal for large, simple roof plans that would traditionally be waterproofed using standard rolls of Protan SE membrane.

Pre-Fabricated membranes enable large areas of Protan membrane to be installed rapidly by reducing on-site hot-air welding operations by up to 70%.

Pre-Fabricated Protan membranes are manufactured off-site, with secret-fix strips factory-welded to their reverse side by high frequency welding technologies. The secret-fix strips are spaced at regular centres, usually 1.00m to simulate 1.00m-wide rolls installed in a Protan Standard Overlap system, however the spacing can be reduced to account for high wind uplift pressures.

Pre-Fabricated membranes significantly reduce the volume of membrane required, as the number and width of overlaps between adjacent rolls of membrane is minimised.